As electronic technologies continue to advance toward higher integration, lighter structures, and long-term reliability, the flexible PCB has become one of the most impactful innovations in circuit design. Its ability to bend, flex, and adapt to unconventional spaces makes it indispensable in automotive systems, medical devices, industrial equipment, and other applications where rigid boards fall short. This article highlights the major advantages of flexible PCBs and outlines the essential specifications of SprintPCB flexible PCB solutions.

What Is a Flexible PCB?

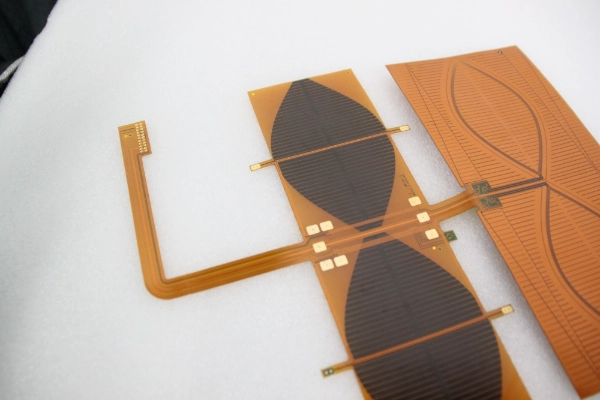

A flexible PCB is fabricated on a bendable substrate—typically polyimide (PI) or polyester (PET)—allowing the board to flex without losing electrical integrity. While the fundamental circuit principles are similar to those of rigid PCBs, the materials and structure are engineered to handle repeated bending, movement, or installation in tight geometric spaces.

This adaptability allows designers to overcome spatial limitations and mechanical challenges, enabling electronic products to become thinner, lighter, and more structurally efficient.

Key Advantages of Flexible PCBs

1. Optimized Use of Space

Flexible PCBs can fold, twist, and route through constrained areas, letting them fit into compact housings where rigid boards cannot.

This characteristic reduces the need for bulky connector assemblies and long wiring harnesses, promoting cleaner internal layouts and supporting highly compact product designs.

2. Superior Reliability Under Stress

Because flexible PCBs tolerate vibration, movement, and extreme temperature variations, they perform exceptionally well in demanding environments.

Automotive electronics, for example, benefit greatly from the fatigue resistance of flexible PCBs, ensuring stable operation even after years of mechanical stress.

3. Effective Thermal Dissipation

Thermal performance is crucial for high-density and high-power circuits.

Flexible PCBs distribute heat more evenly due to their thin, uniform material structure, helping protect components from heat-induced failure and improving overall system stability.

4. Long-Term Cost Benefits

Although flexible PCBs may initially be more expensive to produce, they often lower costs in the long run. The reduction in connectors, cables, and assembly steps leads to simpler manufacturing and fewer potential points of failure.

Their compact form factor can also reduce packaging, storage, and transportation expenses.

SprintPCB Flexible PCB Specifications

SprintPCB offers flexible PCB manufacturing with a range of customizable options designed to match diverse engineering needs. Key specifications include:

-

Layer Count: 1–6 layers

-

Material Options: Polyimide or polyester

-

Profiling Methods: Laser cutting, punching, milling

-

Copper Thickness: 8 μm–70 μm

-

Overall Thickness: 0.05 mm–0.80 mm

-

Maximum Panel Size: 250 mm × 610 mm

-

Minimum Trace/Space: 0.05 mm / 0.05 mm

-

Surface Finishes: HASL, LF HASL, OSP, ENIG, tin, silver, gold finger

These capabilities allow SprintPCB to support high-density layouts, flexible interconnects, and specialized performance requirements across a wide range of applications.

Final Thoughts

The flexible PCB is reshaping the landscape of electronic design. Its structural versatility, mechanical resilience, and compatibility with compact device architectures make it an essential choice for modern engineering challenges.

By opting for SprintPCB flexible PCBs, you gain access to durable materials, reliable processing techniques, and a suite of customization options that ensure optimal performance—no matter the application. From prototyping to full-scale production, SprintPCB delivers flexible PCB solutions built to meet tomorrow’s technological demands.

https://www.sprintpcb.net/blogs/Unlocking-the-Potential-of-Flexible-PCBs-in-Modern-Applications.html

https://www.sprintpcb.net/pcb/Flexible-PCB.html

www.sprintpcb.net

SprintPCB

More Stories

Smart Dynamic Cycling Helmet with Warning Lights for Real Roads

JK durable OLED screen for phone repair: Troubleshooting "Black Screen" and flex cable connection issues

Reducing Line Losses and Enhancing Efficiency with Sun.King Capacitors for AC Railway Power Networks