As manufacturing industries demand higher efficiency, tighter tolerances, and greater production flexibility, CNC gear hobber technology continues to evolve rapidly. From automotive and motorcycle manufacturing to reducers, pumps, and synchronous belt pulleys, modern gear production relies on advanced CNC hobbing machines that combine automation, precision, and intelligent control. These trends are reshaping how gears are produced and setting new standards for quality and productivity.

Automation Driving Productivity Gains

Automation has become a central trend in CNC gear hobber technology. Modern machines increasingly integrate automatic loading and unloading systems, robotic arms, and flexible fixturing solutions. These features reduce manual intervention, shorten cycle times, and enable continuous, unattended operation.

Automated CNC gear hobbers also improve consistency by minimizing human error. In high-volume production environments such as automotive and motorcycle manufacturing, automation ensures stable quality across large batches while significantly lowering labor costs.

Higher Precision for Demanding Applications

Precision is a defining requirement in today’s gear manufacturing. CNC gear hobbers now achieve tighter tolerances and improved surface finishes through enhanced machine rigidity, high-performance spindles, and advanced motion control systems.

High-rigidity machine structures reduce vibration during high-speed cutting, allowing for greater accuracy even at elevated feed rates. Combined with precise CNC control algorithms, modern gear hobbing machines can consistently meet the demanding requirements of reducers, pumps, and transmission components.

High-Speed and High-Efficiency Machining

To keep pace with global production demands, CNC gear hobbers are designed for high-speed and high-efficiency operation. Optimized cutting parameters, powerful drive systems, and efficient chip removal enable faster material removal without compromising tool life or surface quality.

High-speed CNC gear hobbing significantly improves throughput, making it ideal for mass production while still supporting flexible manufacturing needs for small and medium batch sizes.

Smart Manufacturing and Digital Integration

Smart manufacturing is transforming CNC gear hobbing from a standalone process into a connected, data-driven system. Modern CNC gear hobbers feature intelligent monitoring functions that track machine status, tool wear, and production data in real time.

Integration with manufacturing execution systems and industrial networks allows manufacturers to analyze performance, predict maintenance needs, and optimize production planning. This digital connectivity improves equipment utilization and supports the transition toward intelligent factories.

Flexible Solutions for Diverse Industries

Today’s CNC gear hobbers are designed to support a wide range of industries and gear types. From automotive and motorcycle components to reducers, synchronous belt pulleys, and pump gears, flexibility is essential. Modular machine configurations and advanced CNC programming make it easier to adapt to different gear specifications and production requirements.

This versatility enables manufacturers to respond quickly to changing market demands while maintaining high quality standards.

Professional CNC Gear Hobber Manufacturing Expertise

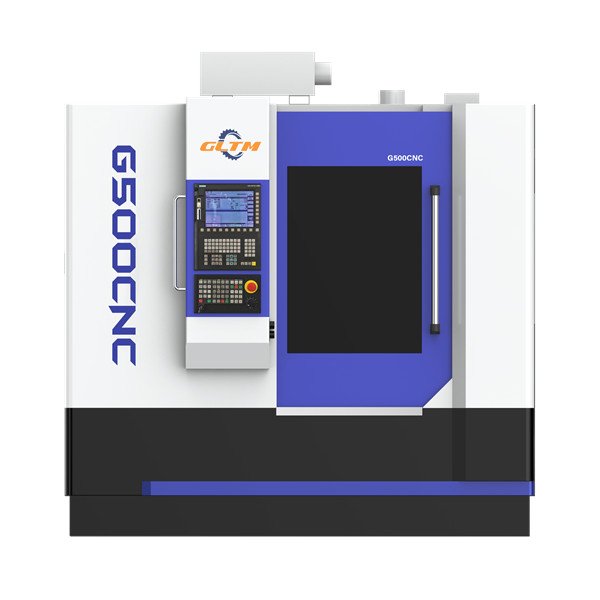

Behind advanced technology is strong manufacturing capability. GLT Machinery (GLTM/GLT) is a professional Chinese manufacturer of CNC gear hobbing machines. Guided by a design philosophy focused on high rigidity, high efficiency, and high reliability, GLT Machinery develops high-speed, high-efficiency CNC gear hobbers for global customers.

GLT Machinery has successfully provided comprehensive gear cutting solutions for industries including automotive, motorcycles, reducers, synchronous belt pulleys, and pump manufacturing, earning recognition for performance and reliability.

The Future of CNC Gear Hobbing Technology

As automation, precision, and smart manufacturing continue to advance, CNC gear hobber technology will play an increasingly important role in modern production lines. Manufacturers who invest in high-performance, intelligent CNC gear hobbing machines will gain a competitive edge through improved efficiency, consistent quality, and flexible manufacturing capability.

www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT)

More Stories

A Practical Guide to Industrial Plane Locks: How to Select the Right Plane Lock for Cabinets and Equipment

Reliable Pressure Sensor Solutions for Industrial Applications

Benefits of Automated Food Metal Detectors in High-Speed Production