The China International Battery Fair (CIBF) once again proved to be a premier platform for innovation and industry exchange in the global battery sector. Mikrouna, a leader in advanced lithium battery equipment and automation technology, proudly participated in the event, showcasing its latest technologies and turnkey solutions for the lithium battery production industry.

Showcasing Our Lithium Battery Automation Production Line

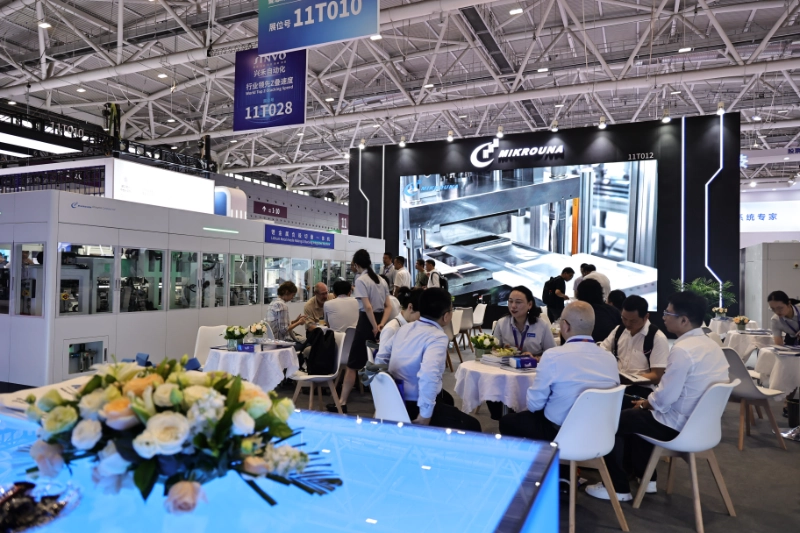

One of the major highlights of Mikrouna's booth was the Lithium Battery Automation Production Line project case. This integrated solution drew significant attention from industry professionals and technical experts alike. By demonstrating real-world application scenarios and automation capabilities, Mikrouna successfully communicated its engineering strength and deep understanding of the lithium battery manufacturing process.

This production line exemplifies how Mikrouna delivers precision, reliability, and scalability—helping battery manufacturers optimize their production workflow, increase yield, and reduce operational costs.

Featured Equipment on Display

At CIBF, Mikrouna presented several key machines that form the backbone of high-performance lithium battery manufacturing. These included:

1. Lithium Metal Preparation Equipment

-

Lithium-Copper Composite Integrated Machine

Designed to combine lithium and copper materials into a composite structure, this equipment offers high-speed precision for metal processing.

-

Lithium Metal Strip Extrusion Machine

Enables efficient production of lithium metal strips with precise thickness control—ideal for modern battery applications.

2. Lithium Metal Battery Anode Making & Stacking Integrated Machine

This all-in-one solution automates the anode fabrication and stacking process, significantly reducing manual labor and improving consistency in lithium metal battery production.

3. Sealed Drying Room/Chamber

An essential part of moisture-sensitive battery manufacturing, Mikrouna’s sealed drying room ensures a low-humidity environment for material handling and electrode assembly, safeguarding product integrity.

4. Dry Electrode Making Equipment

-

Dry Electrolyte Mixing Machine

Provides efficient and homogeneous mixing of dry electrolytic materials for solvent-free battery production methods.

-

Three-Roll Dry Electrolyte Film Making Machine

A precision system that forms high-quality dry electrolyte films, paving the way for next-generation eco-friendly battery technologies.

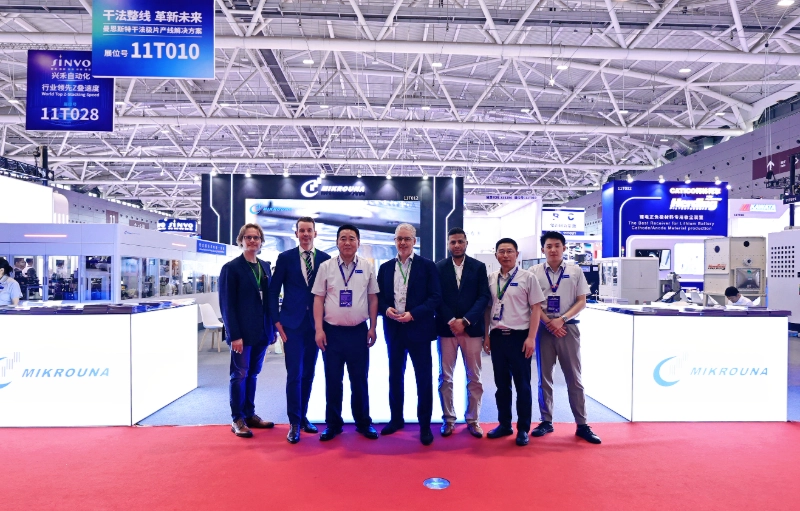

Engaging with Industry Professionals

Throughout the exhibition, Mikrouna's booth attracted a high volume of visitors, including engineers, procurement managers, R&D teams, and battery technology experts. Our team engaged in valuable conversations, explored potential collaborations, and received highly positive feedback on our machinery and automation solutions.

Looking Ahead

Mikrouna remains committed to leading innovation in the battery equipment field. Our participation in CIBF not only demonstrated our cutting-edge solutions but also strengthened our global presence in the lithium battery manufacturing ecosystem. We thank all visitors who stopped by our booth and look forward to further collaboration.

Whether you're seeking state-of-the-art lithium metal preparation equipment, dry electrode processing systems, or full-scale automated battery production lines, Mikrouna is your trusted partner for high-performance, future-ready solutions.

www.li-ion7.com

Mikrouna

More Stories

Key Features to Look for in a Single-Acting Scotch Yoke Pneumatic Actuator + Bevel Gear

Dingshengzun Launches Comprehensive Onshore Oilfield Equipment Solutions for Industry

ATLAS COPCO 3002600320 PACKAGING KIT