A car engine timing chain is like a bike chain. It connects important gears so they move together. The chain links the crankshaft and camshaft. This makes sure valves and pistons move at the right time. When timing is correct, the engine runs smooth and steady.

-

The timing chain keeps valve timing exact. This helps stop rough idling, misfires, or rattling sounds.

-

Good timing means your engine uses fuel well. It also gives you steady power when you drive.

Key Takeaways

-

The timing chain links the crankshaft and camshaft. It helps engine parts move together at the right time. This makes the engine run smoothly and work well.

-

Timing chains are made from strong metal. They last much longer than timing belts. With good care, they can last as long as the engine.

-

You might notice problems with the timing chain. These include rattling sounds, slow speeding up, engine misfires, or the check engine light turning on. Finding these signs early can help you avoid expensive repairs.

-

Changing the oil often and using the right oil is important. This keeps the timing chain slippery and stops it from wearing out. It helps the chain last longer and keeps your engine working well.

-

If you replace a worn timing chain on time, you protect your engine from big problems. This also helps your car keep its power and use less gas.

Car Engine Timing Chain

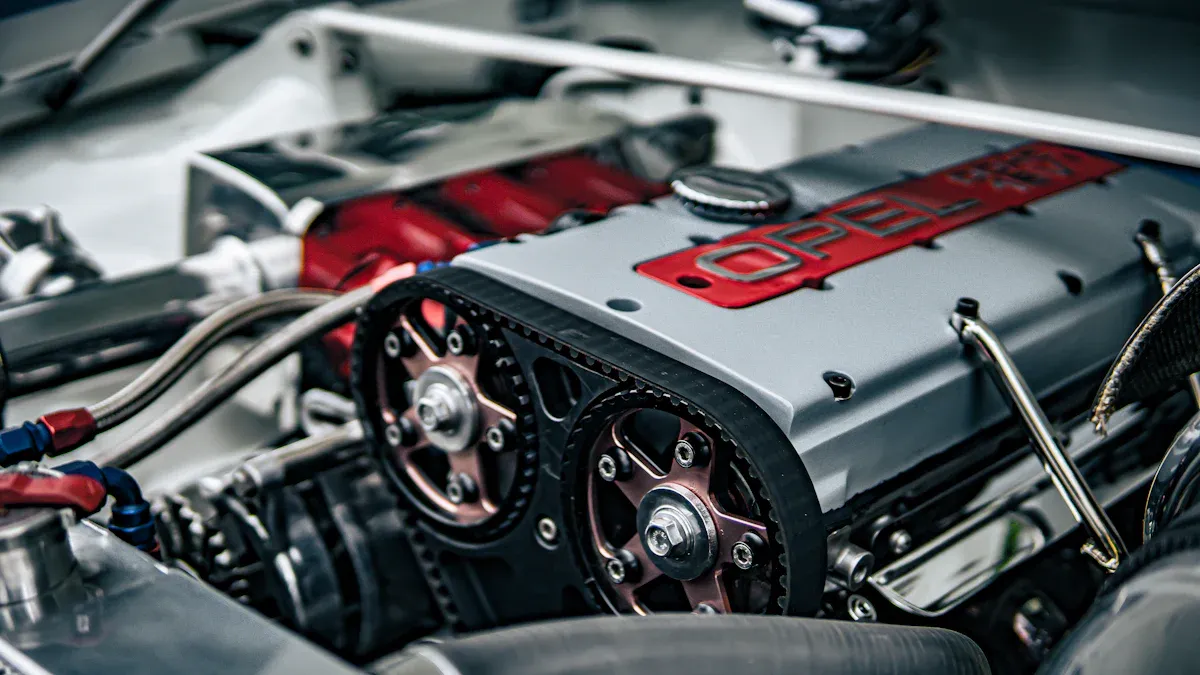

What It Is

A car engine timing chain is a strong metal chain. It links the crankshaft and camshaft together. The crankshaft is at the bottom of the engine. It turns when the pistons move up and down. The camshaft is at the top of the engine. It controls when the valves open and close. The timing chain connects these two parts. This makes sure they move together at the right time.

Manufacturers use very tough materials for timing chains. Here is a table that shows some materials and what they do:

|

Material Type |

Key Properties |

Effect on Durability and Performance |

|---|---|---|

|

High-strength alloy steel |

High strength, corrosion resistance, toughness, hardness |

Handles high stress and impact, resists corrosion, keeps timing reliable |

|

Cast iron (ductile iron) |

Wear resistance, shock absorption |

Lasts long, absorbs shocks, keeps gears stable |

|

High-hardness quenched alloy steel |

High wear resistance |

Reduces wear, extends timing chain life |

|

Steel with high chromium content |

Corrosion resistance |

Protects against harsh engine conditions |

Most timing chain gear sets use cast iron because it is strong. Some better systems use billet gears or special bearings. These help reduce friction and wear. This helps the timing chain last longer.

Main Function

The timing chain’s main job is to keep the crankshaft and camshaft moving together. This is called timing. When timing is right, the valves open and close at the best moments. This lets air and fuel in and lets exhaust out. If timing is wrong, the engine can run rough or get damaged.

You might want to know how a timing chain is different from a timing belt. Here is a table to compare them:

|

Aspect |

Timing Belt |

Timing Chain |

|---|---|---|

|

Material |

Reinforced rubber |

Metal (high-strength steel) |

|

Typical Lifespan |

60,000 to 100,000 miles |

Often lasts lifetime of engine (150,000+ miles) |

|

Maintenance |

Needs regular replacement |

Needs less frequent maintenance |

|

Noise Level |

Quieter |

Can be noisier |

|

Replacement Cost |

Less expensive |

More expensive |

|

Performance |

Smoother, quieter |

More durable, handles higher temperatures |

Timing chains last much longer than timing belts. They can handle more heat and stress. This is why many new engines use timing chains. New technology makes timing chains even stronger. You can trust them to keep your engine running well for a long time.

How It Works

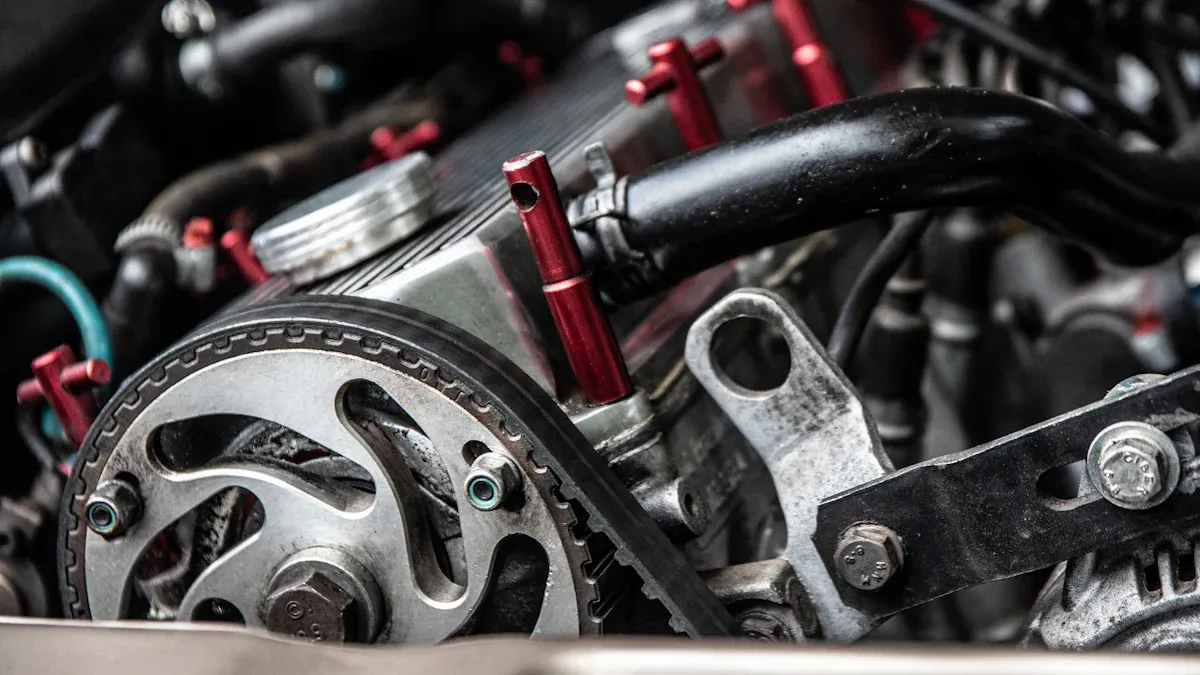

Synchronizing Parts

When you start your car, the crankshaft begins to spin. The car engine timing chain connects the crankshaft to the camshaft. As the crankshaft turns, it pulls the timing chain. The chain then rotates the camshaft at just the right speed. This movement keeps the engine parts working together in perfect harmony.

A timing chain tensioner keeps the chain tight. This tensioner stops the chain from becoming loose or skipping teeth on the gears. If the chain slips, the engine parts lose their rhythm. The tensioner makes sure the timing chain stays in place, so the crankshaft and camshaft always move together. This tight connection is key for high performance and smooth driving.

Tip: If you hear rattling from your engine, the timing chain might be loose. A loose chain can cause big problems for engine timing and performance.

Engine Timing

Engine timing means making sure the valves and pistons move at the right moments. The timing chain controls this process. When the crankshaft turns, the chain moves the camshaft. The camshaft opens and closes the valves. The valves let air and fuel in and push exhaust out. If the timing is off, the valves open or close at the wrong time. This can cause the engine to misfire or run rough.

You want the timing to be exact. Good engine timing means the fuel burns completely. This gives you strong acceleration and high performance. If the timing chain wears out or breaks, the engine loses its timing. You might notice poor acceleration, rough idling, or even trouble starting your car. Sometimes, you will see extra smoke from the exhaust or hear strange noises. These are signs that the timing chain is not keeping the engine in sync.

Here are some problems that happen when engine timing is not correct:

-

Valves open or close at the wrong time, causing misfires.

-

The engine may idle roughly or hesitate when you press the gas.

-

You might see more exhaust smoke or notice a loss of power.

-

The engine can fail to start if the timing is very bad.

-

Metal shavings in the oil can show up, which means parts are wearing out.

Precise engine timing is critical for high performance and reliability. When the timing chain works well, your engine runs smoothly and uses fuel efficiently. You get the best performance every time you drive. High performance engines need perfect timing to deliver power and speed. Even a small mistake in timing can lower performance and cause damage.

Note: Keeping your timing chain in good shape helps your engine last longer and keeps your car running at its best.

Timing Chain Problems

Symptoms

You can spot timing chain problems early if you know what to look for. Your car may give you several warning signs. Here are some common symptoms:

-

You hear a rattling or ticking noise from the engine, especially when you start the car or press the gas pedal. This noise often means the chain is loose or stretched.

-

The check engine light turns on. The car’s computer senses that the timing is off and warns you.

-

You notice poor acceleration. The car feels sluggish or slow to respond.

-

The engine misfires or stalls. This happens when the timing chain slips and the spark plugs fire at the wrong time.

-

You find metal shavings in the engine oil. This shows that parts of the chain or gears are wearing out.

If you see any of these signs, you should visit a mechanic soon. Early action can help you avoid costly engine repair.

Causes

Several things can cause timing chain problems. The most common reasons include:

-

Stretching of the chain over time. High mileage puts stress on the chain, making it longer and looser.

-

Lack of maintenance. Skipping oil changes or using the wrong oil can cause the chain and its parts to wear out faster.

-

Failure of the tensioner. The tensioner keeps the chain tight. If it fails, the chain can slip or jump.

-

Poor quality oil or dirty oil. Dirty oil does not lubricate the chain well, which leads to faster wear.

You may wonder how timing chain issues compare to timing belt problems. Here is a table to help you see the differences:

|

Aspect |

Timing Chain |

Timing Belt |

|---|---|---|

|

Frequency of Issues |

Less frequent; mainly from poor maintenance |

More frequent; rubber wears out faster |

|

Severity of Issues |

More severe and costly to repair |

Can be severe if ignored |

|

Maintenance Interval |

Can last the life of the engine |

Needs replacement every 60,000–100,000 miles |

|

Repair Cost |

Higher ($1,000–$3,000) |

Lower ($500–$1,000), but more often |

|

Durability |

Metal, handles stress and heat |

Rubber, wears out from age and use |

|

Noise |

Can be noisier |

Quieter |

A car engine timing chain keeps the camshaft and crankshaft in sync. If the chain fails, the timing falls out of alignment. This can cause poor fuel efficiency and higher emissions. Regular oil changes and timely checks help you avoid these problems and keep your car running smoothly.

Maintenance and Replacement

Lifespan

You can expect a timing chain in most modern cars to last between 150,000 and 200,000 miles. Many manufacturers design these chains to work for the entire life of your vehicle. This durability helps your car deliver steady performance year after year. Timing chains last longer than timing belts because they use strong metal links. If you follow the recommended maintenance schedule, you help your engine keep high performance for a long time.

Regular care and good driving habits help your timing chain reach its full lifespan.

When to Replace

Even though timing chains are tough, some things can shorten their life. You may need to replace the chain if you notice problems or if your mechanic finds wear during a checkup. Here are some common reasons for early replacement:

-

Skipping oil changes or using poor quality oil causes the chain to wear out faster.

-

Driving in stop-and-go traffic, towing heavy loads, or facing extreme heat puts extra stress on the chain.

-

Some engines have weaker tensioners or guides, which can lead to faster wear.

If you need a replacement, expect a complex job. The average cost ranges from $2,047 to $2,674, with most of the expense coming from labor. Mechanics must remove many engine parts to reach the chain. They often replace related parts like tensioners and guides at the same time. Delaying replacement can lead to engine damage and loss of high performance.

|

Cost Component |

Estimated Range (USD) |

Notes |

|---|---|---|

|

Total Cost |

About Author |

More Stories

Exothermic Welding Connection: Advancing Reliable Grounding with Sunlightweld

Долговечный промышленный насос: надежность, эффективность и инновации от Цзяхэ

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency