When planning a construction, architectural, or industrial project, selecting the right materials is key to ensuring both function and aesthetic value. Among surface-treated aluminum options, Mechanically Polished Aluminum Profiles have gained popularity for their mirror-like finish, smooth texture, and modern appeal. Whether you're working on a high-end façade, a sleek office interior, or precision machinery, choosing the right profile can make all the difference. As one of China’s largest aluminum production bases, Jiangxi KaiMeiDa Aluminum offers a wide range of mechanically polished aluminum profiles tailored to meet diverse application needs. Here’s a detailed guide to help you make the right decision.

1. Understand What Mechanically Polished Aluminum Profiles Are

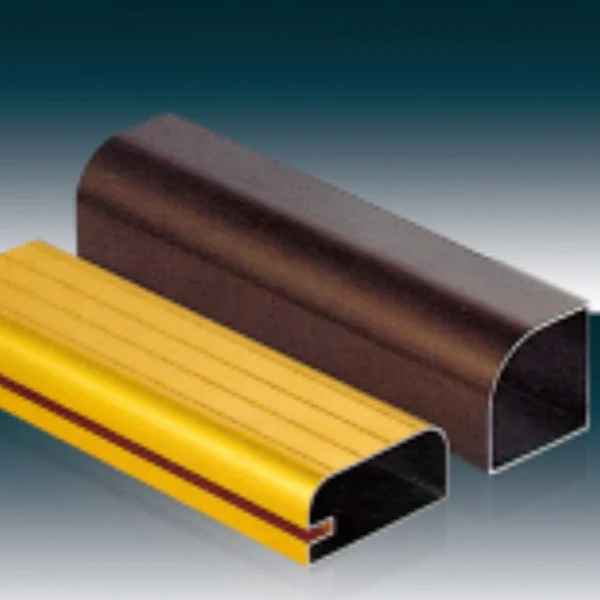

Before making a selection, it’s important to understand what you’re choosing. Mechanically polished aluminum profiles are extruded aluminum components that have undergone a multi-stage polishing process using abrasive materials and mechanical equipment. This process removes surface imperfections, enhances reflectivity, and creates a smooth, shiny finish.

Unlike anodized or chemically polished surfaces, mechanical polishing emphasizes surface texture and visual appeal, making it ideal for projects where appearance matters as much as performance.

2. Determine Your Project Requirements

Not all projects demand the same performance characteristics. Start by identifying your primary needs:

-

Is the profile used indoors or outdoors?

-

Does it need to support structural weight or just provide visual appeal?

-

Will it be exposed to moisture, UV rays, or chemicals?

For instance, if you're working on a curtain wall system for a commercial building, KaiMeiDa’s polished profiles with high flatness and corrosion resistance would be ideal. On the other hand, profiles for interior office partitions may prioritize aesthetic consistency and light reflection.

3. Assess Surface Quality and Finish Level

One of the key selling points of mechanically polished aluminum profiles is their surface finish. Depending on your application, you may need:

-

Mirror-polished surfaces for high-end decoration

-

Satin or semi-gloss finishes for subtle elegance

-

Low-reflection finishes for functional industrial use

KaiMeiDa Aluminum employs imported polishing and inspection equipment from Japan and Germany, ensuring high surface uniformity and minimal defects. Their quality control system follows the ISO9001 and GB/T 5237.1~6—2017 standards, which ensures the polish meets both aesthetic and functional demands.

4. Choose the Right Alloy and Temper

Different aluminum alloys offer different mechanical and corrosion-resistant properties. For example:

-

6063-T5 is ideal for architectural applications due to its excellent anodizing and polishing properties.

-

6061-T6 offers higher strength and is suitable for structural or mechanical use.

KaiMeiDa provides full alloy and temper support depending on your project type. Their in-house mold making and extrusion capabilities mean you can request customized alloys and shapes to match your specifications.

5. Verify Size, Shape, and Compatibility

The aluminum profile must match the structural and dimensional requirements of your project. Consider:

-

Wall thickness

-

Cross-section shape

-

Slot and mounting compatibility

-

Tolerance standards

KaiMeiDa’s facility covers 200 acres and houses 12 extrusion lines, supporting a wide range of profile designs including window and door frames, curtain wall profiles, and customized industrial profiles. Whether you need a standard shape or a unique design, they can produce profiles based on your CAD drawings.

6. Consider Post-Processing Options

Mechanically polished profiles can also be paired with other treatments to enhance durability or color:

-

Anodizing for corrosion resistance

-

Electrophoretic coating for a uniform surface layer

-

Wood grain transfer for aesthetic variety

KaiMeiDa operates 2 sandblasting lines, 2 spray coating lines, 4 wood grain transfer lines, and a full anodic oxidation line—giving clients flexibility to enhance polished profiles with additional finishes.

7. Ensure Supplier Quality and Support

Choosing a reliable manufacturer is just as important as choosing the product. KaiMeiDa Aluminum is not only the largest aluminum production base in Jiangxi Province but also a brand trusted under names like "Kai Mei Da", "Jian Peng", and "Yin Kai". With a team of 400 skilled workers, strict 5S field management, and cutting-edge QC systems, they offer robust after-sales support, consistent quality, and fast delivery options thanks to their location near major highways and airports.

Conclusion

Selecting the best mechanically polished aluminum profile for your project is not just about the shine—it's about compatibility, durability, and the reputation of the supplier. From architectural beauty to industrial functionality, these profiles can significantly enhance both the appearance and performance of your final product. With its strong technical foundation, complete production lines, and commitment to quality, Jiangxi KaiMeiDa Aluminum stands out as a trusted partner for your polished aluminum profile needs.

When it comes to combining strength, aesthetics, and precision, mechanically polished aluminum profiles offer a premium solution for today’s demanding projects.

www.jxkmdly.com

Jiangxi KaiMeiDa Aluminum

More Stories

Exothermic Welding Connection: Advancing Reliable Grounding with Sunlightweld

Долговечный промышленный насос: надежность, эффективность и инновации от Цзяхэ

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency