Dry type transformers are undergoing a period of significant technological advancement, driven by rising demand for safer, more efficient, and more environmentally responsible power distribution solutions. As global industries push for lower energy losses, improved insulation systems, and more reliable electrical infrastructure, next-generation dry type transformers are emerging as a central component of modern energy strategies.

This article explores the innovative design features that define the newest generation of dry type transformers and highlights how Dingmao (DM), a long-established manufacturer with deep technical heritage, is helping advance the industry. For readers who want to understand how these innovations translate into real-world applications, the topic offers both technical clarity and practical takeaways.

The Rise of Next-Gen Dry Type Transformers

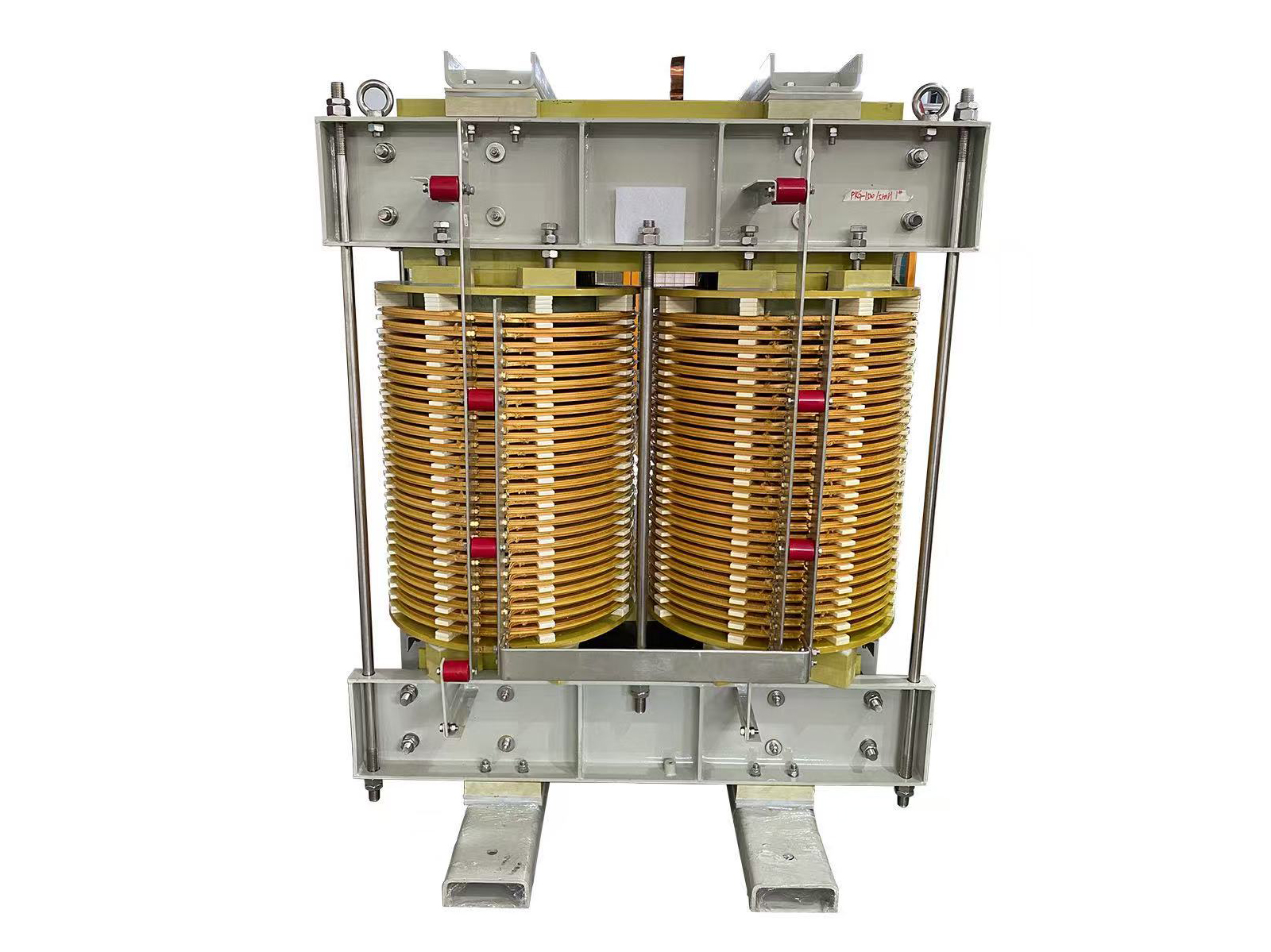

Dry type transformers, unlike oil-filled units, use air or solid materials for cooling and insulation. Their inherent safety—no risk of oil leakage or combustion—makes them ideal for urban facilities, high-rise buildings, hospitals, offshore platforms, renewable energy stations, and data centers.

Today’s next-gen units go far beyond traditional cast-resin or VPI designs. Manufacturers are integrating new magnetic materials, advanced thermal management, improved coil structures, and smart monitoring functions. These enhancements are driven by practical needs: reduced maintenance, longer service life, better energy efficiency, and reliable operation in harsh or sensitive environments.

For a detailed overview of dry type transformer products used across industries, you can explore this resource:

<a href="https://www.dmtransformer.com/dry-type-transformers.html">Dry Type Transformers</a>

1. Optimized Core Design Using Advanced Materials

At the heart of every transformer is its core, and innovations at this level directly impact performance and energy efficiency.

Amorphous and High-Performance Silicon Steel Options

One of the most impactful advances is the integration of amorphous metal technology, which dramatically reduces core losses. Dingmao (DM) has decades of expertise in transformer core manufacturing, initially rooted in its collaboration with GE Prolec. This partnership began with the production of amorphous steel cores for distribution transformers and helped DM develop a deep understanding of magnetic material behavior and processing.

As the company expanded operations from Taiwan into China, DM introduced mature transformer manufacturing processes that improved quality consistency while lowering overall production costs. This allowed the company to offer high-performance cores with tight tolerances, smooth magnetic pathways, and low-loss operation—all critical elements in next-generation dry type transformers.

Precision Jointing and Stress Reduction Techniques

Mechanical stress in cores leads to vibration, noise, and increased losses. Advanced dry type transformers now employ optimized step-lap designs, improved annealing techniques, and non-stress clamping systems to maintain material integrity.

DM’s vertically integrated manufacturing approach ensures that each core—from raw material handling to final assembly—meets strict international standards. This commitment helps customers achieve stable power distribution and long operational lifespans.

2. Enhanced Coil Engineering for Greater Reliability

Coils are another area of rapid innovation, as winding techniques and insulation systems have a major influence on a transformer’s thermal stability, mechanical strength, and environmental resistance.

Improved Resin and Insulation Systems

Next-gen dry type transformers often use enhanced epoxy resin formulations or high-temperature insulation materials that resist thermal aging and moisture absorption. These materials contribute to:

-

Extended service life

-

Higher overload capacity

-

Stable operation in humidity-dense or corrosive environments

Manufacturers like DM focus heavily on material qualification and testing. Through decades of engineering experience, the company has refined processes such as vacuum casting and encapsulation to ensure uniform resin penetration and excellent dielectric performance.

Mechanical Reinforcement for Fault Durability

Short-circuit forces can damage coils if not properly supported. Modern transformers incorporate mechanical reinforcements such as reinforced winding supports, stable clamping structures, and optimized conductor placement.

By combining these techniques with quality control measures developed over decades, DM ensures its coils maintain dimensional stability, even during extreme electrical events.

3. Advanced Thermal Management and Cooling Innovation

Thermal performance is a key determinant of transformer lifespan. Poor heat dissipation accelerates insulation aging and reduces reliability.

Airflow-Optimized Geometry

Next-generation dry type transformers feature coil and core geometries designed to maximize natural airflow. Gaps and channels are positioned to promote effective convection cooling.

DM’s engineering teams apply computational analysis and practical field feedback to refine airflow paths. These incremental improvements translate into lower operating temperatures and reduced need for forced-air cooling systems.

Optional Fan-Assisted Cooling Systems

For applications where load fluctuations are expected, optional forced-air cooling can increase capacity and improve thermal stability. Advanced fan control systems ensure efficiency by engaging only when needed.

This flexible approach allows facility managers to manage energy use while ensuring dependable performance during peak loads.

4. Smart Monitoring and Predictive Maintenance Features

Although dry type transformers are known for low maintenance requirements, intelligent monitoring technology is becoming increasingly valuable.

Real-Time Condition Monitoring

Embedded sensors can now monitor:

-

Temperature rise

-

Humidity

-

Partial discharge activity

-

Coil vibration

-

Load variations

These data points allow operators to detect anomalies early, plan maintenance more efficiently, and avoid unexpected downtime.

Integrated Data Interfaces

Next-gen dry type transformers support communication protocols that integrate seamlessly with plant management systems. This gives energy managers and engineers clear visibility of asset performance across multiple locations.

DM’s commitment to continuous improvement includes adopting digital tools that complement its high-quality mechanical and electrical designs. With decades of manufacturing experience and a focus on long-term reliability, DM offers transformers that combine physical durability with modern intelligence.

5. Structural and Environmental Durability

As dry type transformers are increasingly installed in demanding environments, manufacturers must design for durability.

Protection Against Dust, Moisture, and Corrosion

Modern units often feature enclosures with enhanced sealing, protective coatings, and anti-corrosion treatments suitable for coastal, industrial, or high-pollution areas.

DM’s products follow strict international standards and are designed to exceed them when possible, ensuring stable operation in a wide range of conditions.

Seismic and Vibration-Resistant Design

In regions with seismic activity or where transformers are placed on elevated platforms, mechanical stability is critical. Reinforced bases, vibration-resistant mounting hardware, and strengthened enclosure frames help maintain alignment and structural safety.

6. Sustainability and Energy Efficiency Improvements

Environmental responsibility is a major driver in modern transformer design.

Reduced Energy Losses

Lower no-load and load losses directly reduce power consumption across the grid. Through improved core materials, optimized winding designs, and precise manufacturing control, next-gen dry type transformers achieve significantly improved efficiency.

Lower Environmental Impact

With no oil used for cooling, dry type transformers present lower environmental risk. Improved material selection, recycling initiatives, and reduced energy waste all contribute to more sustainable operations.

DM’s growth over multiple decades—from its origins in Taiwan in 1970 to its position as a global energy industry partner—demonstrates a long-term commitment to sustainable, customer-focused manufacturing. The company’s continuous investments in technology, quality improvement, and international compliance have helped it become a preferred supplier worldwide.

Conclusion

Next-generation dry type transformers represent a meaningful step forward in safety, efficiency, and reliability. Advances in core materials, coil engineering, thermal management, monitoring technology, and structural design are helping industries meet modern energy challenges with confidence.

Dingmao (DM), with its family-run heritage, decades of technical expertise, and global manufacturing capabilities, continues to play an important role in this evolution. By combining high-quality materials, refined production processes, and a commitment to exceeding international standards, DM offers dry type transformers that perform reliably in a wide range of applications.

As energy infrastructure becomes more demanding, the innovations driving next-gen dry type transformers will remain central to building efficient, stable, and sustainable power systems.

www.dmtransformer.com

Dingmao (DM)

More Stories

Exothermic Welding Connection: Advancing Reliable Grounding with Sunlightweld

Долговечный промышленный насос: надежность, эффективность и инновации от Цзяхэ

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency