1. What are Rare Earth Permanent Magnets?

Rare earth permanent magnets are intermetallic compounds formed from rare earth elements (such as Neodymium Nd, Samarium Sm, Dysprosium Dy, Terbium Tb) and transition metals (such as Iron Fe, Cobalt Co). They possess extremely high permanent magnetic properties.

Simply put, they are the strongest permanent magnets currently available on Earth. Their magnetic energy product (a key indicator of magnet strength) far exceeds that of traditional ferrite or Alnico magnets.

2. Core Characteristics and Advantages

Extremely High Magnetic Energy Product:

This is their most prominent advantage. It means that for the same size, rare earth magnets can store and release more magnetic energy, achieving "small size, great magnetic force."

High Coercivity:

Coercivity measures a magnet's resistance to demagnetization. High coercivity makes rare earth magnets very stable and less likely to lose their magnetism due to external magnetic fields or aging.

High Remanence:

They can maintain strong magnetism after the external magnetizing field is removed.

High Energy Density:

This is crucial for applications requiring high efficiency and lightweight design, such as electric vehicle motors.

Disadvantages:

-

High Cost: Raw materials (especially heavy rare earths like Dysprosium and Terbium) are expensive.

-

Limited Temperature Resistance: Especially for Neodymium magnets, they are prone to demagnetization at high temperatures, although this can be improved by adding heavy rare earth elements.

-

Susceptible to Corrosion: Neodymium magnets, composed mainly of iron and neodymium, are prone to oxidation and rust, and usually require surface coating (e.g., nickel plating, zinc plating, epoxy resin).

3. Main Types

There are two main types of commercialized rare earth permanent magnets:

1. Neodymium Iron Boron Magnets

Composition: Primarily Neodymium, Iron, Boron.

Reputation: Often called the "King of Magnets," they are the strongest permanent magnetic material known to date.

Advantages:

-

Extremely high magnetic energy product, performance far surpasses other magnets.

-

High cost-performance (among rare earth magnets).

Disadvantages:

-

Relatively low operating temperature (typically between 80–200°C, depending on the grade).

-

Prone to corrosion, requires surface protection.

Grades:

Identified by “N” series, e.g., N35, N42, N52. Higher numbers indicate higher maximum energy product.

High-temperature series include N35SH, N42UH, etc.

2. Samarium Cobalt Magnets

Composition: Primarily Samarium and Cobalt.

Advantages:

-

Excellent high-temperature performance, operating temperatures can reach 250–350°C.

-

Strong corrosion resistance, usually does not require plating.

-

Good temperature stability; magnetic properties change little with temperature.

-

Low temperature coefficient; stable over wide temperature ranges.

Disadvantages:

-

Magnetic energy product is lower than Neodymium magnets.

-

Raw material cost is higher (contains strategic metal Cobalt).

Applications:

Used in aerospace, defense, high-temperature motors, and other fields requiring extreme stability.

3. Performance Comparison Table

| Characteristic | Neodymium | Samarium Cobalt | Ferrite |

|---|---|---|---|

| Magnetic Energy Product | Extremely High | High | Low |

| Coercivity | High | Very High | Medium |

| Operating Temperature | Medium (80–200°C) | High (250–350°C) | Medium |

| Corrosion Resistance | Poor (requires coating) | Excellent | Excellent |

| Cost | Medium | High | Very Low |

| Raw Materials | Nd, Fe, B | Sm, Co | Iron Oxide, Sr/Ba |

4. Brief Introduction to Manufacturing Process

Using Neodymium Iron Boron as an example, the primary method is “Powder Metallurgy”:

-

Melting: Raw materials are melted in a vacuum induction furnace to form alloy ingots.

-

Milling: Ingots are crushed and ground into fine powder.

-

Pressing and Forming: Powder is aligned in a strong magnetic field and pressed into shape.

-

Sintering and Tempering: Sintered under vacuum or inert gas; then heat treated to enhance magnetic properties.

-

Machining: Sintered magnets are brittle and require precision processing.

-

Surface Coating: Plating or spraying to prevent corrosion.

-

Magnetization: Final product is magnetized using a strong pulsed magnetic field.

5. Main Application Areas

Rare earth permanent magnets are critical materials for modern technology and green energy.

Automotive Industry:

-

Electric/Hybrid Vehicles: Traction motors and generators.

-

Traditional Vehicles: Micro motors (windows, seats, wipers), sensors, EPS systems.

Industrial Motors:

High-efficiency permanent magnet synchronous motors.

Consumer Electronics:

Hard drives, smartphone speakers, vibration motors, headphones.

Wind Power Generation:

Direct-drive permanent magnet generators with high efficiency and low maintenance.

Medical Equipment:

MRI components, precision surgical instruments, medical pumps.

Aerospace and Defense:

Satellites, radar, guidance systems, drone motors (often Samarium Cobalt).

Energy-Efficient Home Appliances:

Inverter motors for air conditioners and refrigerators.

6. Future Development and Challenges

-

Reducing Heavy Rare Earth Dependence:

Optimization techniques like grain boundary diffusion aim to reduce Dysprosium/Terbium usage. -

Recycling and Circular Economy:

Recovering magnets from end-of-life electronics is essential for supply security. -

Finding Alternative Materials:

New materials such as iron-nitride magnets are under research. -

China’s Dominance:

China leads in global rare earth production and NdFeB magnet manufacturing.

In summary, rare earth permanent magnets—especially Neodymium magnets—are the “invisible champions” driving modern technology and energy transformation. From smartphones to electric vehicles and wind turbines, their powerful magnetic performance supports a more efficient and intelligent world.

Rare Earth Permanent Magnetic Material

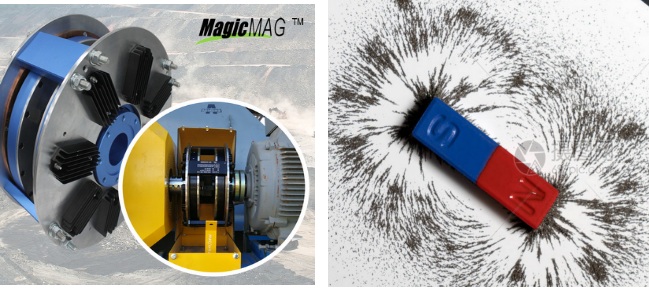

Permanent-Magnet Machine

Permanent Magnet Coupler (PMC) & Permanent Magnet Drive (PMD)

Magnetic Levitation Train

https://www.magicmag-tech.com/introduction-to-rare-earth-permanent-magnets.html

SHANGHAI GAOLV E&M Technology Co.,Ltd.

More Stories

Exothermic Welding Connection: Advancing Reliable Grounding with Sunlightweld

Долговечный промышленный насос: надежность, эффективность и инновации от Цзяхэ

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency