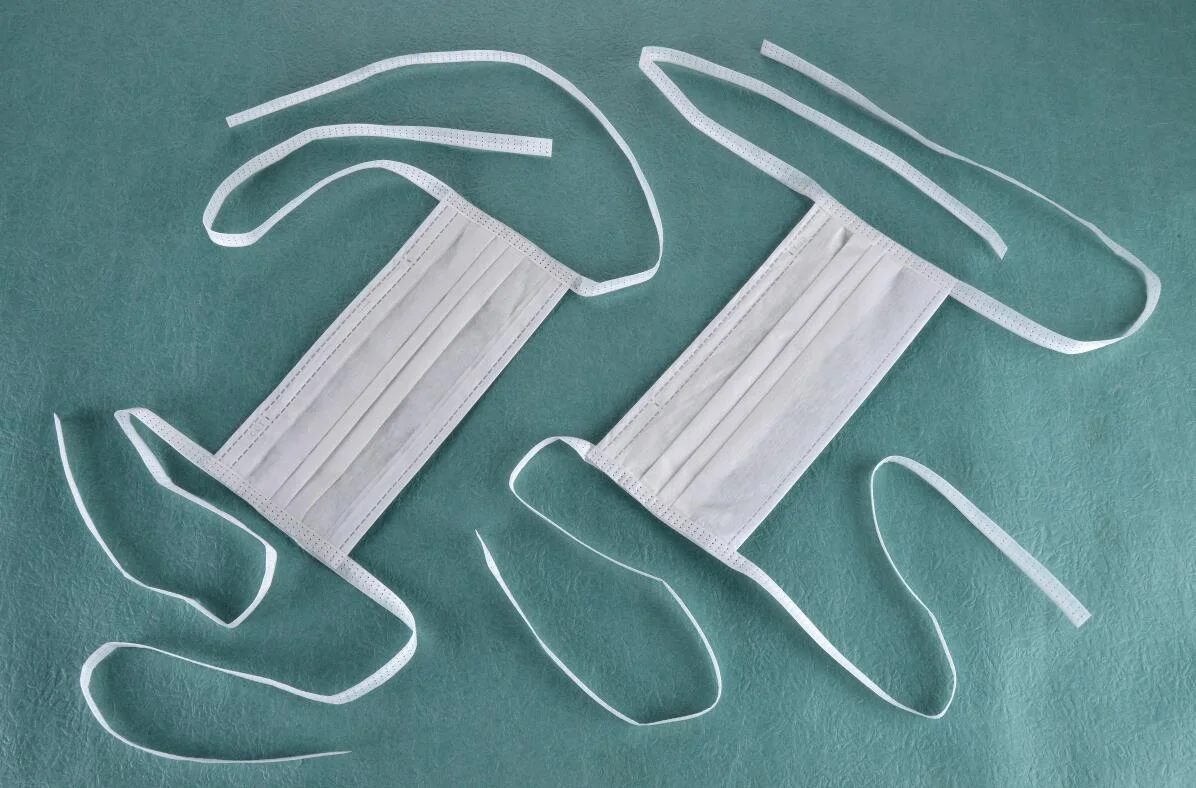

In the realm of personal protective equipment (PPE) manufacturing, precision and efficiency are non-negotiable. Mask tie tape sealing machines play a crucial role in the production of medical and industrial face masks, ensuring that each mask is securely assembled and ready for use. Whether you’re a production line operator or a factory manager aiming to optimize output, understanding how to operate these machines effectively can significantly enhance both product quality and productivity.

In this blog, we’ll walk through a detailed, step-by-step guide to operating mask tie tape sealing machines, while highlighting Broadfair’s innovative contributions to this space as a leading high-tech enterprise.

Step 1: Understand the Machine Structure

Before operating any machinery, a clear understanding of its components is essential. A typical mask tie tape sealing machine includes:

Control panel (touch screen or button-based interface)

Feeding mechanism for tie tapes

Ultrasonic sealing system

Cutting system

Conveyor belt or feeding platform

Broadfair’s sealing machines are ergonomically designed for user-friendliness, integrating modular components that simplify maintenance and enhance adaptability to different mask types.

Step 2: Prepare the Materials

Ensure you have the following materials on hand:

Pre-cut or rolled mask bodies

Elastic or non-elastic tie tapes (as required)

Power source and air compressor (if required)

Broadfair’s machines are compatible with a wide range of materials, offering flexibility for various production standards.

Step 3: Machine Setup and Calibration

Turn on the main power and let the machine initialize.

Set the machine parameters via the control panel:

Sealing temperature

Ultrasonic power level

Tape length and positioning

Align the mask body and tie tapes according to the guides.

Perform a trial run with a single unit to verify correct positioning and sealing.

Thanks to Broadfair’s R&D team, their machines feature automatic calibration options that reduce setup time and increase first-pass yield.

Step 4: Start Production

Once calibrated, initiate the continuous or semi-automatic production mode:

Place the mask body on the conveyor.

The machine feeds the tie tape, positions it, seals it using ultrasonic welding, and trims the tape if needed.

The completed mask moves along the conveyor for inspection or packaging.

Broadfair’s sealing machines come equipped with intelligent sensors that detect misfeeds or sealing errors, halting production automatically to prevent waste.

Step 5: Monitor and Maintain

To ensure consistent output and machine longevity:

Inspect ultrasonic horns and sealing pads daily.

Clean tape residue or debris after every shift.

Lubricate moving parts as per the maintenance schedule.

Check software updates or firmware patches for enhanced performance.

Broadfair offers dedicated after-sales support, including real-time technical assistance and scheduled maintenance services, making them a reliable partner in long-term operations.

Step 6: Troubleshooting Common Issues

Problem: Tape not sealing properly

Solution: Check ultrasonic settings or clean the horn.

Problem: Tape misalignment

Solution: Recalibrate the feeding guide and sensors.

Problem: Machine stops unexpectedly

Solution: Inspect the emergency stop button or sensor alarms.

Broadfair’s machines are built with diagnostic alerts that display real-time error messages, allowing for quick resolution and minimal downtime.

Why Choose Broadfair?

As a high-tech enterprise integrating research, manufacturing, and sales, Broadfair is at the forefront of automation solutions in the PPE industry. With a commitment to innovation, quality, and service, Broadfair provides:

High-efficiency, low-maintenance sealing machines

Customizable solutions for different mask styles and production volumes

Strong R&D capabilities with a focus on smart automation

Excellent customer service and global distribution

Final Thoughts

Operating a mask tie tape sealing machine doesn’t have to be complex when you have the right tools, training, and equipment. By following these step-by-step instructions—and choosing a reliable partner like Broadfair—you can ensure smooth operations, high output, and consistently high product quality.

For more information about Broadfair’s full range of PPE machinery and automation solutions, visit their official website or get in touch with a representative.

The Benefits of Mask Tie Tape Sealing Machines in Modern Manufacturing

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.

More Stories

FanChu Lubricants Unveils New Stainless Steel Cutting Oil: Advantages, Applications, and Pricing!

How Long Do LiFePO4 Batteries Really Last? Cycle Life Explained

Professional Supplier of Olive Leaf Powder Extract – Olea europaea L. Oleuropein