In the fast-evolving world of engineering and industrial manufacturing, the demand for high-performance, precision-engineered tubing is stronger than ever. Among the various types of steel tubes available today, seamless cold drawn tubes have emerged as a preferred choice for critical applications due to their exceptional mechanical properties, dimensional accuracy, and surface finish.

As a global specialist in steel tube materials, TORICH plays a pivotal role in supplying seamless cold drawn tubes to industries that require durability, reliability, and precision. With a focus on innovation, quality control, and client-centric service, TORICH continues to push the boundaries of steel tube manufacturing.

This article explores the characteristics of seamless cold drawn tubes, their production process, and their wide-ranging applications across modern industries.

What Are Seamless Cold Drawn Tubes?

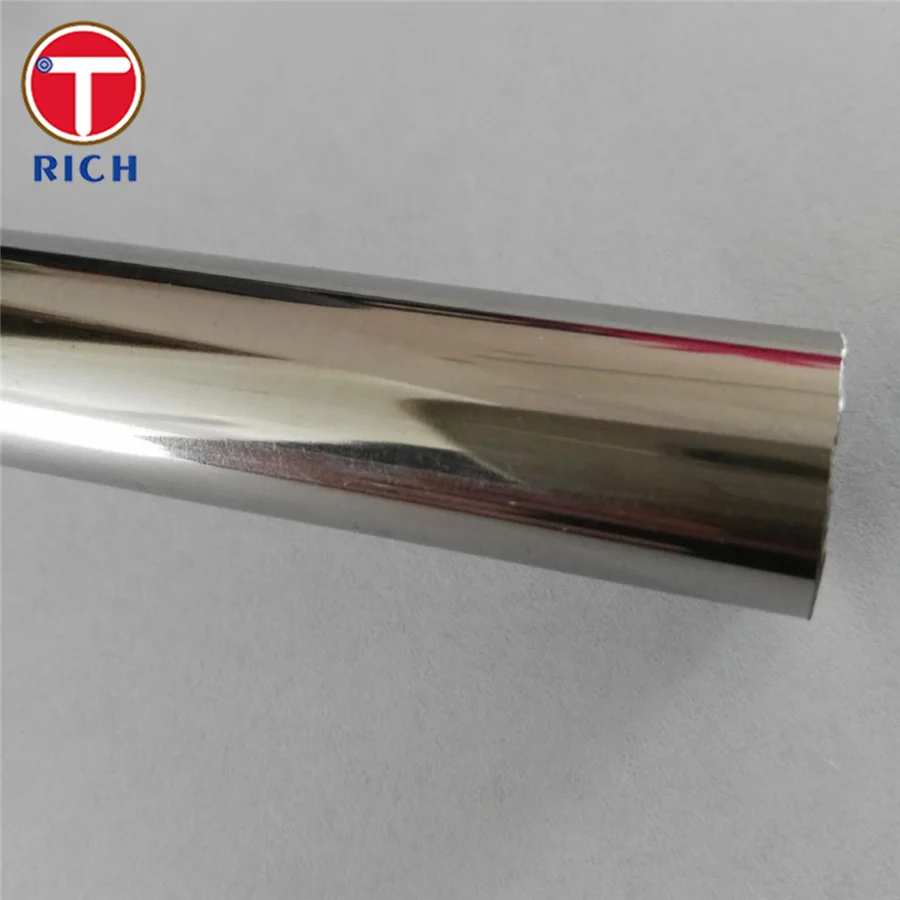

Seamless cold drawn tubes are steel tubes produced without a welded seam, using a cold drawing process to refine the tube’s dimensions, surface quality, and mechanical properties. This method involves pulling a hot-formed seamless tube through a die at room temperature, which reduces its diameter and enhances its overall performance.

Key Features:

High dimensional precision and concentricity

Excellent surface finish

Improved tensile strength and yield

Enhanced machinability

Uniform structure without weld defects

Because of these features, they are ideal for applications where tolerance, strength, and consistency are non-negotiable.

Industrial Applications of Seamless Cold Drawn Tubes

Let’s take a closer look at the major industries where these tubes are making a significant impact:

1. Automotive and Transportation

In the automotive sector, seamless cold drawn tubes are used for shock absorber cylinders, drive shafts, steering components, and fuel injection systems. Their uniform wall thickness and strength make them ideal for safety-critical parts that must withstand high pressure and dynamic loading.

TORICH supplies auto-grade tubing that meets international quality standards (such as DIN, ASTM, and EN), ensuring durability and performance in vehicles across the globe.

2. Mechanical and Hydraulic Systems

These tubes are the backbone of hydraulic cylinders, pneumatic systems, and precision mechanical components due to their smooth interior finish and tight tolerances.

Ideal for seamless cylinder barrels

Minimal friction and wear

Resistance to pressure and fatigue

TORICH offers custom dimensions and steel grades for manufacturers needing exact specifications for their hydraulic or mechanical equipment.

3. Energy and Power Generation

In sectors like oil & gas, nuclear, and renewable energy, cold drawn seamless tubes are used in applications such as:

Heat exchangers

Boiler tubing

Instrumentation lines

Power transmission structures

The absence of weld seams reduces the risk of failure under high-temperature or high-pressure environments—critical in energy systems.

4. Aerospace and Aviation

The aerospace industry demands lightweight, high-strength components. Cold drawn seamless tubes offer:

High fatigue resistance

Lightweight structural integrity

Corrosion resistance (with appropriate alloys)

TORICH supports aerospace applications with aerospace-grade tubing solutions, manufactured to rigorous specifications and compliance certifications.

5. Medical and Laboratory Equipment

Cold drawn tubes are used in precision instruments, surgical tools, and medical diagnostic equipment, where cleanliness, precision, and non-reactivity are essential.

TORICH produces stainless steel tubing tailored for medical-grade applications, ensuring surface smoothness and bio-compatibility.

6. Construction and Structural Engineering

Cold drawn tubes are often used in scaffolding, high-rise structures, and load-bearing frames due to their high strength-to-weight ratio and clean, uniform appearance.

TORICH’s manufacturing capabilities allow for large-volume supply of structural steel tubes with various finishes and treatments.

Advantages of Choosing TORICH

As a trusted manufacturer and global supplier, TORICH International Co., Ltd offers a comprehensive range of seamless cold drawn steel tubes in carbon steel, alloy steel, and stainless steel.

TORICH stands out with:

✅ Over 20 years of manufacturing expertise

✅ Strict quality assurance systems (ISO, TS16949 certified)

✅ Customized production and fast delivery

✅ Global export capability to over 50 countries

✅ Technical consulting and after-sales service

Whether you need standard tubing or tailor-made solutions for demanding environments, TORICH brings the technical know-how and industrial experience to deliver results.

Conclusion

In a world where engineering precision and reliability are paramount, seamless cold drawn tubes provide the strength, performance, and accuracy required across industries. From the engines of a car to the hydraulic lift of an excavator, their versatility and structural integrity are unmatched.

Backed by a commitment to excellence and customer satisfaction, TORICH continues to supply high-quality steel tubing solutions that power the modern world—one tube at a time.

The Importance of Seamless Cold Drawn Tubes in Structural Integrity and Design

www.torichsteel.com

TORICH INTERNATIONAL LIMITED

More Stories

FanChu Lubricants Unveils New Stainless Steel Cutting Oil: Advantages, Applications, and Pricing!

How Long Do LiFePO4 Batteries Really Last? Cycle Life Explained

Professional Supplier of Olive Leaf Powder Extract – Olea europaea L. Oleuropein